BOTTOM LOADING ARMS

Bottom loading offers benefits which cannot be achieved with top loading designs. As it takes place on the ground, it is inherently safer for the operator. It also allows for simultaneous loading of several tank compartments, increasing speed and efficiency of loading. Bottom loading is easily adaptable to vapor recovery systems.

-

BOTTOM LOADING ARM - LNG

This loading arm is especially designed to load LNG products and is suitable for the bottom loading / unloading of road or rail tankers.

The loading arm has a long reach and is suitable for applications where tanker connection flange cannot be accurately positioned.

Because of the robust and high quality design of the swivel joints and the precise loading arm balancing, handling of the loading arm is effortless.

The design of the stainless steel swivel joints are based on the reliable D2000 and are also equipped with an interchangeable bearing module.

The primary and secondary product seal enable the operator to monitor leakage during the whole operating time of the loading arm. In addition, the ball raceway can be purged with dry gas and the swivel joints are designed to meet the requirements of the OCIMF.

SPECIFICATIONS

Sizes:

DN 80

DN100Materials of product carrying parts and swivel joints:Stainless steel

Materials of seals:Fluoroloy-G

Balancing method:Counter weights / Spring cylinder

Design pressure:Max. 20 bar

Design temperature:-170° C to +80° C

-

STANDARD BOTTOM LOADING ARMS - E2824 TO E2839

This type of loading arm is especially designed to load mineral oil or chemical products and is suitable for the bottom loading/unloading of road or rail tankers.

The loading arm has a long reach and is suitable for applications where the tanker connection flange cannot be accurately positioned.

Because of the robust and high quality design of the swivel joints and the precise loading arm balancing, handling of the loading arm is effortless.

SPECIFICATIONS

Sizes:

DN 50

DN 80

DN 100Materials of product carrying parts and swivel joints:

Carbon steel

Stainless steel

Internal lining is possibleMaterials of seals:

Buna

Viton

PTFE

Other seals availableBalancing method:

Spring cylinderDesign pressure:Max. 40 bar up to shut off valve

Design temperature:

-50° C to max 300° C -

BOTTOM UNLOADING ARMS FOR RUSSIAN RAILCARS - E2704

The E2704 rail unloading arm is designed for light oil products, chemicals or high viscose products. It is equipped with a special coupler for the unloading of Russian railcars from underneath. The coupler enables a safe and quick connection, independent to the orientation of the adapter lid.

The long reach of the loading arm also enables connection to rail cars when the adapter is not positioned exactly. Due to the low offset of the swivel joints a minimum vertical height is guaranteed.

Rail loading arms for “white products” are unheated, while the loading arms for viscose products “Mazut” are equipped with an internal heating system. This system guides hot product through the loading arm into the rail car through a special telescopic nozzle assembled in the coupler.

The robust and high quality design of the swivel joints and the spring cylinder balancing gives comfortable and smooth handling of the arm.

SPECIFICATIONS

Sizes:DN 150Material:

Carbon steel

AluminumSeals:

NBR

FPM

PTFE

Special materialsTemperature range:

-50° C to +50° C

Higher or lower temperature on request -

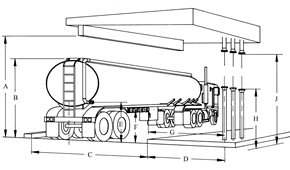

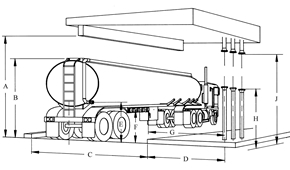

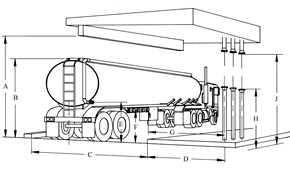

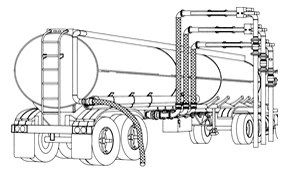

WORLD BOTTOM HOSE LOADER - WE2852

Our WE2852 World Bottom Hose Loader is designed for the bottom loading and unloading of road or rail tankers with all types of fuel.

Tanker side connection is achieved with a 4“ API coupler. The loading arm dimensions are designed to cover the complete API connection area.

A bottom loading station can consist out of up to 5 product arms. The design allows unrestricted cross over of all arms (see data sheet E2701). A separate loading arm for vapor recovery completes the installation.

Our carbon steel swivel joint has a hardened ball race way to provide a long service life. For more details see our data sheet swivel joint D2000 .

For the API Couplers you have various options:

New J0452 (10 bar or 16 bar), optional integrated pump with filter element, if required.

Perolo CAMSEC Coupler (10 bar) with integrated check valve, if required.

J0451 (6 bar), safety interlock feature

K2 & K2P (16 bar), zero spillage by pumping mechanism

J0100 (16 bar), high pressure version; with integrated check valve, if requiredSPECIFICATIONS

A bottom loading station can consist of up to 5 product arms

Material of inlet flange up to valve:

Carbon steelMaterial of elbow-swivel-assembly:

AluminumSeals:Viton

PerbunanDesign pressure:

Depending on the coupler; 16 bar up to shut off valveDesign temperature:-10° C to +80° C

Balancing method:Spring cylinder

-

BOTTOM TRANSFER LOADER - E2033BOTTOM TRANSFER LOADER - E2033

Los cargadores de transferencia inferior proporcionan un alcance extendido que los hace ideales para aplicaciones en las que no es posible localizar con exactitud el vehículo.

Su facilidad de ajuste, el accionamiento extremadamente suave de la compensación del cilindro con resorte, las juntas giratorias de alto rendimiento confieren a este brazo un mayor alcance sin necesidad de un soporte adicional. La compensación del cilindro con resorte permite un movimiento vertical de hasta 95 grados para una fácil alineación y un estacionamiento apartado.

- Los brazos estándar incluyen la junta giratoria D2000 World Series, una junta de bajo perfil y alta resistencia.

- Diversas configuraciones de sellado y elastómeros garantizan un rendimiento duradero para cada aplicación específica.

- No se recomienda para el cruce de varios brazos. Consulte E2573 y E2304.

Especificaciones

Tamaño de la tubería:

De 2″ a 8″Materiales de la ruta del líquido:

Acero al carbono

Acero al carbono/Aluminio

Acero inoxidable 316LPeso aprox.:

3 pulgadas – 118 kg (260 lb)

4 pulgadas – 158 kg (350 lb)

6 pulgadas – 85 kg (410 lb)Alcance:

3 – 96 pulgadas

4 – 108 pulgadas

6 – 108 pulgadas -

BOTTOM SPRING LOADER - E2304

The E2304 Bottom Spring Loader is especially designed for the bottom loading and unloading of road or rail tankers with all type of fuels.

Tanker side connection is achieved with a 4″ API coupler. The loading arm dimensions are designed to allow for covering of the complete API connection area envelope.

Reliable and well proven components:

Emco Wheaton D2000 World Series swivel joints

Emco Wheaton spring cylinder

Robust composite rubber hose or Stainless steel braded hose

Emco Wheaton API dry break coupler

Safe working, easy operation, drip-free welded construction

Bottom Loading Data SheetA bottom loading station can consist of up to 5 product arms. The design allows unrestricted cross-over of all arms.

A separate loading arm for vapour recovery completes the installation.

SPECIFICATIONS

Inlet flange up hose:Carbon steelHose:

Rubber

Alternative Stainless SteelElbow-swivel-assembly:

AluminumSeal:Viton

Buna

Low tempDesign pressure:Dependent on the coupler – 300 psi up to shut off valve

Design temperature:

14°F to +176°FBalancing method:Spring cylinder

-

A-FRAME BOTTOM LOADER - E2313

The E2313 “A” Frame Bottom Loader is recommended for servicing both sides of the platform and for adjacent arm crossover. The secondary arm is available as a rigid pipe or hose.

The “A” Frame Bottom Loader offers the advantages of easy handling, long reach and quality Emco Wheaton technology.

Standard arms feature the D2000 World Series swivel joints for ultra low maintenance and the easy to adjust spring cylinder balance.

SPECIFICATIONS

Pipe Size:

2” through 6”Materials:

Carbon Steel

Aluminum

Stainless steelStandard vertical range of motion:

55° (park position) to -20° (load position)Maximum vertical range of movement:

Up to 95° with spring cylinders -

COUNTERWEIGHT BOTTOM HOSE LOADER - E2573

Designed specifically for tank truck bottom loading in accordance with API Recommended Practice1004:

Counterweight balancing for ease of handling and close center mounting to the API envelope

D2000 World Series swivel joints

Recommended when crossover of three or more products is required

Unique sliding scale weight allows arm to balance in the horizontal position

Design allows for easy adjustment, greater coupling efficiency, and reduced installation time

Complete package of arm, hose, hose cover, outboard swivel joint spacer spool, and API coupler available.ESPECIFICATIONS

4” and 6″ Carbon steel design with 150# inlet flange

4” TTMA hose connections -

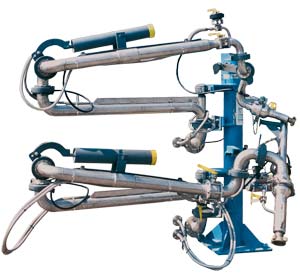

BOTTOM HOSE LOADING STATION - E2852 AND E2701

Our Bottom Hose Loading Station enables efficient loading of tank trucks with simultaneous loading of up to five products plus a vapor arm.

The loading station is designed to enable a totally flexible operation with unrestricted cross-over of all arms.

The loading arms are equipped with our API Couplers.

Our carbon steel swivel joint has a hardened ball race way to ensure a long service life.

ESPECIFICATIONS

- Simultaneous loading of 5 different productsUnrestricted crossoverPetroleum applicationsReliable well proven components:

- Carbon steel swivel jointSpring cylinderRobust rubber hoseAPI dry break coupler

- Adequate space between loading arms and tank truck during fillingFree access for operation and escape wayIndividual, customer designed unitsSpecial materials are available e.g. stainless steel

-

BOTTOM LOADING STATION - E2386

Our E2386 loading arm is especially designed to load products where vapor return is necessary.

It is suitable for the bottom loading/unloading of road or rail tankers with flange connection or coupling.

These loading arms have a long reach and are suitable for applications where tanker connection flange cannot be accurately positioned.

For connection pipes with high weight, the loading arm can be designed with a special 6 swivel configuration with parallel bar and gas spring for balancing the weight of the connection pipe.

Because of the robust and high quality design of the swivel joints and the precise loading arm balancing, the loading arm is very easy to handle.

SPECIFICATIONS

Sizes:

DN 50

DN 80Balancing method:

Spring CylinderProduct Entry:

HorizontalMaterials of product carrying parts:Carbon steel

Stainless steel

Low temperature steelSeal material:Buna

Viton

PTFEDesign pressure:Max. 40 bar up to shut off valve

Design temperature:

-45° C to +300° C