TOP LOADING ARMS

We have designed and manufactured loading arms for more than 60 years. We focus on meeting the needs of our customers and are able to deliver technically advanced solutions to suit almost any application in the world.

-

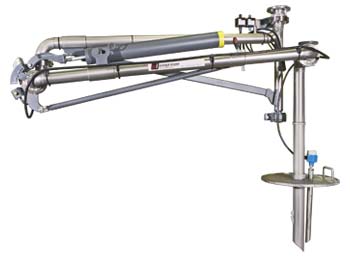

DRUM FILLING LOADING ARM

The Drum Filling loading arm is especially designed to load or unload small compartments such as drums or IBC containers. The loading arm has a long reach and is suitable for applications where the manhole or the connection flange cannot be positioned accurately.

The Drum Filling loading arm can be arrested in the working position. The disadvantages of a traditional hose filling are therefore prevented, i.e. the loading arm cannot slip off the manhole.

The robust design and high quality of the swivel joints provide ease of operation of the loading arm.

SPECIFICATIONS

Material de los componentes de transporte del producto:

Material of product carrying components:

Carbon steel

Stainless steel

AluminumSwivel joint seal: Buna, Viton, Teflon

Special materials:

Available on requestDesign pressure: 16 bar

Design temperature:

-10 to +50 °CVARIANTS

Sizes DN:

50 mm & 80 mm -

LOADING ARM WITH FIXED CONNECTION - E2816 TO E2819 E2615 TO E2618

Our Loading Arm with Fixed Connection is especially designed to load chemical products.

It is suitable for the top loading of road or rail tankers using the manhole. The loading arm has a long reach and is suitable for applications where the manhole cannot be accurately positioned.

Because of the robust and high quality design of the swivel joints and the precise loading arm balancing, handling of the loading arm is effortless.

These variants of Loading Arm are equipped with an additional swivel joint to ensure the flange connection remains horizontal when coupling to road or railcar tankers.

SPECIFICATIONS

Sizes:DN 50

DN 80

DN 100Material of loading arm:

Carbon steel

Stainless steel

(low temperature possible)Seals:Buna

Viton

PTFEBalancing method:Spring cylinder

CounterweightDesign pressure up to shut off valve:

Max. 40 barDesign temperature:

-50° C to +300° CVARIANTS

E2816 – DN 50, 80 – Spring cylinderE2615 – DN 100, 150 – CounterweightE2817 – DN 50, 80 – Spring cylinderE2616 – DN 100, 150 – CounterweightE2818 – DN 50, 80 – Spring cylinderE2617 – DN 100, 150 – CounterweightE2819 – DN 50, 80 – Spring cylinderE2618 – DN 100, 150 – Counterweight -

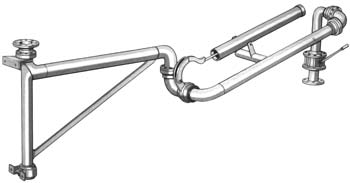

PARALLEL LOADING ARM - E2632

E2632 Parallel Loading Arms with vapor return lines are used for hydrocarbons (e.g. gasoline), toxic and aggressive media. Two boom loaders are connected together to form this loader. All movements are performed in parallel – hence the name: Parallel Arm.

The addvantages are that the loading arm can be operated like a single arm, i. e. it is highly maneuverable. Also, both the product and vapor recovery lines are free from pockets.

By loading with the vapor return line, the product vapor will be recovered through the loading arm. This improves the profitability of the terminal because vaporized product can be recovered and vapor does not pollute the environment.

By loading with a sealed manhole, a high level of protection is achieved for both the operator and the environment.

Legal requirements and regulations (e.g. EU-Norm, TA-Luft) can be met.

The E2632 is technically the best solution for the process of loading with vapor return. The flow path is free from traps which would retain the condensed vapors and emit fumes when the arm is not in use. The design allows heating of the product and vapor line.

The design of the vapor line with swivel joints provides easy handling; a further advantage against the use of hoses.

SPECIFICATIONS

Sizes:

Product DN 50 – Vapor DN 50

Product DN 80 – Vapor DN 50

Product DN 100 – Vapor DN 80

Product DN 150 – Vapor DN 100Materials:

Carbon steel / aluminum

Low temperature steel

Stainless steel

PTFE-linedSeals:NBR

EPDM

PTFE

Special materialsTemperature range:

-50° C to +50° CDesign:

Piggable

Acc. WHG

Acc. VbF

(International)Accessories:Cover plate

Cone

Telescopic drop pipe -

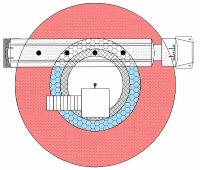

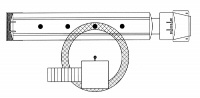

TOP UNLOADING ARM WITH HEATING LINE FOR RAIL CARS - E2710

The E2710 Top Unloading Arm with Heatin Line is especially designed to heat up and unload frozen products. It is suitable for the top loading / unloading of rail tankers.

Because of the robust and high quality design of the swivel joints and the precise loading arm balancing, the loading arm is very easy to hande.

By unloading through the nozzles at the end of the drop pipe, hot product will be sprayed into the vessel. The frozen product in the vessel will be warmed up and can be sucked off through the product pipe. The drop pipe can be turned so that the whole vessel can be reached with hot product.

It is possible to fasten a movable holding bar (covering plate) for a level controller. The up and down movement of the A-length is provided by a pneumatic or hydraulic cylinder.

SPECIFICATIONS

Size:

Suction tube 100 DN

Heating tube 50/80 DNSeals:

FVMQ

PTFE

Special materialsTemperature range:High temperature from -40° C up to +200° C

Accessories:

Cover plate

Support bracket -

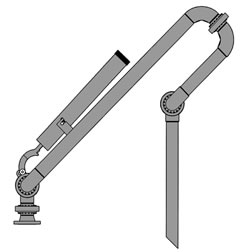

TOP LOADING ARM FOR LIQUEFIED GASES - E2611 E2612

The E2611 E2612 Top Loading Arms are especially designed for the loading and unloading of liquefied gases.

The arm is connected to the rail car compartment by a coupler, especially designed for Russian railcars. The coupler provides a fast and safe connection to the valves of the rail car.

The E2612 Loading Arm is combined with a second recommended Vapor Arm E2611.

This loading arm is designed with two end pipes for unloading. A gas return arm with one end pipe allows another use of unloading the rail car under pressure.

The robust and high quality design of the swivel joints and the spring cylinder balancing provides comfortable and smooth handling of the arm.

The E2611 presents an economic and successful solution for selected applications of loading and unloading liquefied hydrocarbon gases. In distinction to hoses the piping provides safety from explosion, driveway obstructions and condensate losses at site.

SPECIFICATIONS

Sizes:

DN 40

DN 50

DN 80

DN 100Materials:

Carbon steel

Stainless steelSeal materials:

PTFE

Special materialsAllowable temperature range:

-57° C to +110° CAlternative dimensions and materials available on request.

-

TOP LOADING WITH VAPOR RETURN HOSE - E2630

Nuestros brazos de carga superior con manguera de devolución de vapor E2630 se utilizan para hidrocarburos (por ejemplo, gasolina) y agentes tóxicos y nocivos.

El E2630 dispone de nuestro brazo de carga de largo alcance junto con una manguera para la devolución de vapor.

Al realizarse la carga con la manguera de devolución de vapor, el vapor del producto se recupera por medio del brazo de carga. Esto mejora la rentabilidad del terminal, ya que es posible recuperar el producto evaporado. Además, se impide que el vapor contamine el medioambiente. Al realizarse la carga por medio de una boca de hombre sellada, se logra un alto nivel de protección tanto para el operador como para el medioambiente.

Permite el cumplimiento de la normativa y los requerimientos legales (por ejemplo, EU-Norm o la TA-Luft de Alemania).

El E2630 es la solución más económica para el procesamiento de la carga con devolución de vapor. Gracias a su reducido tamaño y a su escaso desplazamiento, su manejo resulta cómodo y sencillo.

El E2630 también se puede utilizar allí donde el espacio disponible es limitado, por ejemplo, en estaciones de carga con techos bajos.

ESPECIFICACIONES

Tamaños:

Producto DN 50 – Vapor DN 50

Producto DN 80 – Vapor DN 50

Producto DN 100 – Vapor DN 80

Producto DN 150 – Vapor DN 100Material:

Acero al carbono/Aluminio

Acero de baja temperatura

Acero inoxidable

Revestido en PTFESellado:

NBR

EPDM

PTFE

Materiales especialesRango de temperatura:

de -50 ºC a +50 ºCDiseño:

Pigado

Acc. WHG

Acc. VbF

(internacional)Accesorios:

Placa de protección

Cono

Tubo buzo telescópico -

UNIVERSAL SUPERIOR CHARGER WE2800 WE2804 WE2800

The universal top loader has been specially designed to meet the requirements of the oil industry applicable worldwide. Thanks to its standardized design, it is the most economical solution for this application.

This type of arm has been designed for the top loading of wagons and tank trucks by means of the manhole.

Thanks to the robust high-quality design of the rotating joints and to a precise balancing of the load arm, it is handled practically without any effort. Its carbon steel rotating joints with hardened guide ring give it a long service life.

SPECIFICATIONS

Sizes:

DN 80

DN 100Material from the flange to the valve:

Carbon SteelValve material: Aluminum

Tube material “A” at exit: Aluminum

Sealed:

Viton

PerbunanDesign pressure:

16 bar up to the shut-off valveDesign temperature:

-10 ºC to +80 ºC -

UNSUPPORTED BOOM LOADER - E2022

Extended reach makes our Unsupported Boom Loader ideal for applications where a vehicle cannot be accurately spotted, see spotting map. It is designed for heavy use and high flow rates that are typical at large terminals.

Standard arms feature the D2000 World Series Swivel Joints for ultra low maintenance and the easy to adjust spring cylinder balance.

SPECIFICATIONS

Pipe size:2” through 12”Materials:

Carbon steel

Aluminum

Stainless steelStandard vertical range of motion for the loading arm:

55° (park position) to -20° (load position)Maximum vertical range of movement:

Up to 95° with spring cylinders. -

SUPPORTED BOOM LOADER - E2025

Our E2025 Supported Boom Loaders are the most versatile of all top loading arms. They provide the greatest mis-spot capability and allow for the greatest reach, see spotting map.

Easy to adjust, super smooth action spring cylinder balance, heavy duty capacity swivel joints and a custom boom support enable these arms to reach even further than the E2022 unsupported boom loader. The standard supported boom loaders have a reach of up to 16 feet, longer reaches and special requirements are available.

Standard arms feature the D2000 World Series Swivel Joint, a heavy duty, low profile joint.

A variety of seal configurations and elastomers ensure long life performance for each specific application.

SPECIFICATIONS

Pipe size:2” through 12”Materials of liquid path:Carbon steel

Carbon steel /Aluminum

Stainless steelStandard vertical range of movement:+55 deg (park position) to –20 deg (loading position)

A World Series spring cylinder can provide up to 95 deg of full movement if required. -

FIXED REACH LOADER - E2110

Our E2110 Fixed Reach Loader is designed specifically for single compartment tank trucks and railroad tank cars. Accurate spotting of railcar or tank truck is required, see spotting map.

Standard arms feature the D2000 World Series swivel joints for ultra low maintenance & the easy to adjust spring cylinder balance.

SPECIFICATIONS

Pipe size:

2” through 12”Materials:Carbon steel

Carbon steel/Aluminum

Stainless steelStandard vertical range of motion:

55° (park position) to -20° (load position)Maximum vertical range of movement:

Up to 95° with spring cylinders -

VARIABLE REACH LOADER - E2112

Versatility of reach makes the E2112 Variable Reach Loader ideal for applications where more than one compartment can be reached without re-spotting the vehicle.

Also known as a Pantograph Unit, the E2112 is recommended for medium reach applications less then 11 feet. Standard arms feature the D2000 World Series swivel joints for ultra low maintenance & the easy to adjust spring cylinder balance.

SPECIFICATIONS

Pipe Size:

2” thorough 12”Materials:

Carbon Steel

Carbon Steel/Aluminum

Stainless SteelStandard vertical range of motion:

55° (park position) to – 20° (load position)Maximum vertical range of movement:

Up to 95° with spring cylinders -

SUPPORTED BOOM ARMS - E2800 TO E2803 E2808 TO E2811

Our Supported Boom Arms are designed to handle all media. They are suitable for the top loading of road or rail tankers using the manhole.

The loading arms have a long reach and are suitable for applications where the manhole cannot be accurately positioned. Because of the robust and high quality design of the swivel joints and the precise loading arm balancing, handling of the loading arm is effortless.

Due to its strong design, this loading arm can be equipped with all required accessories.

SPECIFICATIONS

Sizes:

DN 50

DN 80

DN 100

(DN 150 available on request)Materials of loading arm:

Carbon steel

Stainless steel

(low temperature possible)Seal material:

Buna

Viton

PTFEDesign pressure:

Max. 40 barDesign temperature:

-50° C to +300° CBalancing method:

Spring cylinder

CounterweightAccessories:

Holding device for filling position

Parallel bar -

FIXED REACH LOADER - E2804, E2805, E2812, E2813 (US: E2110)

Our Fixed Reach Loader is especially designed for the top loading of Road or Rail tankers using the manhole. The loading arm has a fixed reach and is suitable for applications where the manhole can be accurately positioned.

Because of the robust and high quality design of the swivel joints and the precise loading arm balancing, handling of the loading arm is effortless.

This loading arm is designed for petroleum and chemical applications.

SPECIFICATIONS

Sizes:

DN 50

DN 80

DN 100

DN 150Balancing method:

Spring cylinder

CounterweightMaterial of inlet flange up to valve:

Mineral oil – Carbon steel

Chemicals – Carbon steel, stainless steelMaterial of valve:

S.G. ironMaterial of “A”-tube to outlet:

AluminumSeals:

Mineral oil – Buna, Viton, (no PTFE)

Chemicals – Buna, Viton, PTFEDesign pressure (up to shut-off valve):Mineral oil – max. 19 bar

Chemicals – max. 40 bar -

VARIABLE REACH LOADER - E2806 E2807 E2814 E2815 (US: E2112)

Our Variable Reach Loader is especially designed for the top loading of road or rail tankers using the manhole. The loading arm has a variable reach and is suitable for applications where the manhole cannot be positioned accurately.

Because of the robust and high quality design of the swivel joints and the precise loading arm balancing, handling of the loading arm is effortless. This loading arm can be used for petroleum and chemical applications.

SPECIFICATIONS

Sizes:

DN 50

DN 80

DN 100

DN 150Balancing method:Spring cylinder

CounterweightMaterial of inlet flange up to valve:

Mineral oil – Carbon steel

Chemicals – Carbon steel, stainless steelMaterial of valve:

C.G. ironMaterial of “A”-tube to outlet:

AluminumSeals:Mineral oil – Buna, Viton

Chemicals – Buna, Viton, PTFEDesign pressure (up to shut-off valve):Mineral oil – max. 19 bar

Chemicals – max. 40 bar